Overall, bottle cutting is very easy to do, and after testing other competitors, we found our bottle cutter to be one of the best working for the value. However, we often hear from customers having trouble getting a clean separation or they claim the cutter blade is worn out.

99.99% of the time we have found that customer issues is not from the cutter or the blade itself. We test every return we receive from customers claiming that it doesn’t work and everyone has cut bottles perfectly on the first try.

Education on Bottle Cutting is Key

So lately, we have been aiming to provide better education to explain how to properly cut the bottle and why you are not getting perfect separation.

And the reason being for bottles cracking?

Answer: It isn’t scored properly or adequately.

Tips That Will Ensure Perfect Cuts

The below tips explain how to get bottles to cut perfectly. First of all, glass is fragile and isn’t forgiving so it has to be done right. If you may a slight mistake, it will crack all the way down the glass. Follow the below tips in combination with our professional bottle cutter used successfully by thousands of people and we will guarantee you will never have an issue cutter bottles again.

Tip 1: Consistently apply down-ward pressure on the bottle so that it scores a heavy solid line into the glass while turning.

The score line needs to be consistently scored. To do this, remember these suggestions to perfect this before you start:

- Keep one hand positioned in between the front 4 rollers & the other hand on the bottleneck while applying pressure with both. IMPORTANT: Adjust the blade up for a good contact point– required for perfect cuts!

- Position the cutter unit on lower ground such as a coffee table so that you have more leverage in applying consistent downward pressure. This is the key to success every time too!

- While turning, make sure to keep the bottle end against the back brace at all times to keep a straight cut.

- Do not go over the score line more than once with the cutter. However, it is recommended to go over faintly scored areas a second time so the whole line is consistent around.

Tip 2: Inspect Score Line Before Using Hot/Cold Separation Cycles—IMPORTANT!

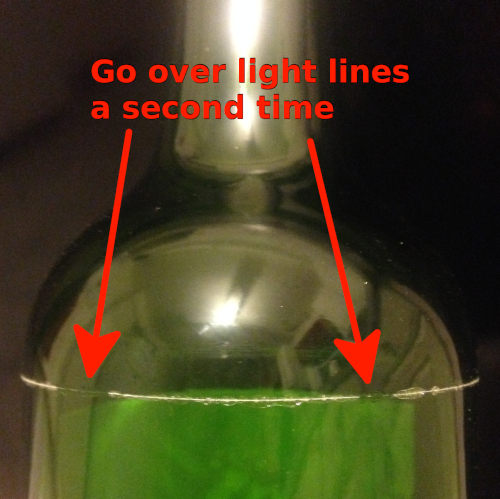

It is important to turn a consistent score line depth or the bottles may crack in the hot/cold separation cycles. Observe any areas that are lighter than the rest of the bottle and score only those areas a second time so the line looks perfectly consistent around.

To further explain a scenario that may cause your bottles to break or separate with jagged areas, please see the below picture. In the picture, you will notice there are two short sections (maybe about 1/4″ long) that are slightly less defined. It is obviously that those short sections are scored lighter than the rest. These areas will cause the bottle to break incorrectly. To prevent this, simply re-score these sections only.

New Attachment Tool to Ensure Perfect Scoring Pressure

If you are still have trouble applying consistent pressure and scoring a deep line, we have recently developed an add-on attachment device to do this correctly. Please stay tuned to more details coming shortly.